Features

Research

Strategies & Innovations

New pump in town

MIT PhD student invents new kind of centrifugal pump, the ‘variable volute’

August 30, 2021 By Colleen Cross

You can watch a short video of Hilary Johnson describing her invention, the variable volute pump, at groundwatercanada.com.

Photo courtesy Lemelson-MIT Prize/Lemelson Foundation

You can watch a short video of Hilary Johnson describing her invention, the variable volute pump, at groundwatercanada.com.

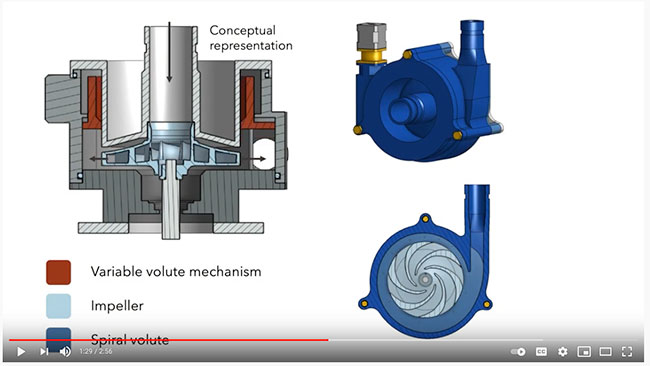

Photo courtesy Lemelson-MIT Prize/Lemelson Foundation What’s new in pumps? Something significant, as it turns out. MITgraduate student Hilary Johnson invented a centrifugal pump with adaptive geometry that changes the volume of the pump in real time to match variable flow rates in the system.

Johnson, a doctoral student in mechanical engineering at the Massachusetts Institute of Technology, calls it the “variable volute” pump and according to sponsor Xylem Inc., it’s the first in a new category of pump.

The mechanism does something engineering experts previously thought very difficult – it physically adjusts to more efficiently move water based on immediate need, resulting in energy and cost savings.

Johnson, who won a prestigious Lemelson-MIT Student Prize for her invention, spoke about her work in a video call with Ground Water Canada.

The technology of hydraulic pumps is often overlooked in the drive to meet green technology goals due to inefficiency, Johnson says. “That’s a big missed opportunity because hydraulic pumps move water in every aspect of our lives.” Pumps consume six per cent of electricity in the U.S., much of which is wasted because pumps can’t adjust to meet variable flow demands.”

The inventor believes variable volute pumps have the potential to significantly improve efficiency and operating range across applications by adjusting the spiral fluid passages to match the flow rate.

Challenge accepted!

Johnson developed this technology in collaboration with Xylem Inc. and with mentorship from the university’s Abdul Latif Jameel Water & Food Systems Lab (J-WAFS), which receives funding from founding sponsor Xylem for activities, events and direct research conducted by faculty and their students.

In 2018 Xylem called for proposals to improve the centrifugal pump:

“Traditionally, the volute was a fixed volume, but water flow rates in most applications are variable. Because the volute cannot expand or contract to meet the changing system flow rate, larger or multiple pumps are needed to accommodate high demand, but are underutilized during times of lower demand. This is a waste of energy and capital, with negative environmental and economic consequences. Industry needs pumps that can adapt to fluctuating flow needs to maximize efficiency and reduce environmental and financial costs. Unfortunately, volute size has never been adaptable, presenting a unique challenge to even expert engineers.”

With the guidance of her advisor, Prof. Alex Slocum, Johnson took up the challenge. She gained early insight into pump fundamentals through experiments, prototypes, and analysis to better understand control variables for pumps. Variable speed drives are a well-known control method, but the actual volume or size of the pump has not been commercially implemented, Johnson says.

“That was the start of my work. It’s a centrifugal pump with adaptive geometry that changes the volume of the pump in real time to match the flow rate of the system. This improves efficiency, operating range and reliability.”

Pandemic pivot to backyard testing

Johnson has been working on the technology for about three years. She used as her baseline pump a Goulds 3642 2HP (bronze fitted) centrifugal pump designed for commercial clean-water applications such as water circulation and general-purpose pumping. Best efficiency BEP operation is 70 gallons per minute and 90 feet of head.

Developing expertise at the intersection of machine design and fluid dynamics, she especially enjoys the iterative process of analysis, prototyping and testing. Prototypes were manufactured using a combination of selective laser sintering 3D printing with nylon materials, machined aluminum baseplate, and traditional hardware like radial o-ring, mechanical seals, and wear rings. She collected real time flow, pressure, torque, speed, voltage, and current data to monitor the operation and efficiency while adjusting the pressure head using a globe value in a test loop.

Unable to access her industrial scale experimental setup when the pandemic hit, Johnson created a small-scale lab for testing at her home. The backyard testable pump setup served as a way to quickly develop ideas and a scalable template based on fluid equations. She has now scaled back up to industrial flows of 80-120 GPM for testing efficiency and reliability to complete her PhD.

‘It’s so simple’

Johnson worked with Xylem’s chief hydraulic engineer Paul Ruzicka and mechanical engineer Chris Felix to get up to speed on problems and solutions tried in the past and expand the mechanism’s range and productivity.

An exciting moment came for Johnson in the test lab when her hypothesis was finally supported by data. The engineers pulled the data up after doing experiments and declared, with some surprise, that “This actually works!”

“Early data shows that changing the volute to match the flow rate leads to efficiency across a broader range of flows,” Johnson says. She’s cautious to generate too much hype before the new pump is proven in the field. “When I hear an operator talk about how it’s improved reliability in their plant, then I’ll celebrate.” Passionate about design, she says the greatest compliment she received was people saying, “It’s so simple. Great ideas don’t often start out simple, but through clever refinement elegantly simple configurations emerge.”

Hilary Johnson manufactured variable volute pump prototypes using 3D printing with nylon materials and machined aluminum. Johnson works at the intersection of precision machine design and fluid dynamics.

Photo by Gurkaran Singh, courtesy Hilary Johnson

How may the pump be used?

The pump has potential applications in clean water, submersible pumps, wastewater, oil and gas, Johnson explains.

“I can see a couple of really neat possibilities,” she says, citing a paper in the journal Applied Energy she co-authored with Prof. Slocum and Dr. Kevin Simon. “For wastewater treatment as well as many applications pumps are oversized to meet rare high flows scenarios. This variable volute pump would potentially enable a plant to install fewer pumps to handle the same capacity.”

Irrigation is a potential area of application. Switching between fields, for example, is a scenario with high variability. “I’m looking to Xylem’s expertise to develop a strategic product market fit,” Johnson says.

Jeff Lopes, manager of the University Partnerships & Programs at Xylem, says, “We think about what would be a good application for a pump to improve operational efficiency. It has potential to help in almost any application.” He says there are manufacturing considerations as well. “We want to use the invention where it can do the most good and is cost-effective,” he says. The idea is to “find forward-thinking customers, prove it out, then extend it to other customers.”

Xylem supports research

“Pumps are an old technology and the engineering of the pump has been nailed down,” Lopes says. “Trying to make a significant advance is a stubborn problem.” Although Xylem has a broad array of highly efficient products and significant advancements have been made in pumps in the past, there hadn’t been major advancements in improving operational efficiency,” he says.

“When pumps are designed, they’re designed around a best-efficiency operating point. The volute is designed so it’s most efficiently catching and directing the water at that operating point.”

Xylem sees the variable volute pump as the first in a new category of pumps. Prior to this invention there were three major pump hardware innovations: the curved impeller, the motor-driven pump and the VFD pump, which can adjust impeller speed and pumping power as operating conditions change. The fourth phase, which he calls adaptive hydraulics, can change not only the quantity of power and speed of the impeller but also compensate by adjusting the geometry of the volute.”

In this way it improves the efficiency of the pump – that’s the innovation.

Lopes’ background is also in mechanical engineering. Part of his role is to find challenging and important problems for the company to collaborate on with universities, technology companies and non-governmental organizations.

“You think about the massive water challenges that affect everybody globally. We’re fairly large but we’re just one company,” Lopes says. “Xylem has a good reputation for open innovation. You have to invest in the future. Starting by getting students interested in water is important to us.”

MIT filed a patent for the variable volute pump in fall 2020 and Xylem is poised to license and commercialize the technology, Johnson says. “I’m excited to see this go from benchtop through commercialization,” she adds.

Future plans

Johnson is grateful to her advisors and mentors at Xylem and MIT, especially Prof. Alex Slocum, of the Precision Engineering Research Group.

It seems the sky’s the limit for Johnson. “I’m excited about creating impact in the world. I grew up in Oregon, which is normally blessed with abundant, clean water,” she says. While finishing high school in Mostar in Bosnia and Herzegovina at a United World College, she saw the infrastructural and human impacts of war. “At the time, they didn’t have fully developed wastewater treatment plants,” she adds. Concerned, she wrote her senior thesis using system dynamics to study aquifer contamination from seeping wastewater. She shared her work with the city’s water board.

“I’m excited to continue working at the nexus of water and energy. I think infrastructure innovation: the pumps, pipes, valves, and hydropower, will be key to sustaining our cities through the next century.”

Watch a short video of Hilary Johnson describing her invention: the variable volute pump.

Print this page