Products

Products

Revamping system design

New, more efficient heat pumps require longer loop systems.

July 5, 2012 By Stan Marco

Over the past few years, thousands of geothermal heat pump systems have

been installed across Canada in response to the demand for more

cost-effective, energy-efficient and renewable heating and cooling

solutions for home and business.

Over the past few years, thousands of geothermal heat pump systems have been installed across Canada in response to the demand for more cost-effective, energy-efficient and renewable heating and cooling solutions for home and business. Along the way, the industry has learned how important it is to select the right-sized equipment and loop systems to maximize heating and cooling efficiency. Designing the right system from the outset will ensure that home and business owners reap the benefits of their geothermal system for years to come.

|

|

Never will system design be more important than in the coming year. A number of geother-

mal manufacturers and distributors, including my own company, are on the verge of introducing new heat pump equipment that is expected to raise the bar on energy efficiency. Some companies are boasting that their new equipment will increase today’s energy efficiency by as much as 30 per cent.

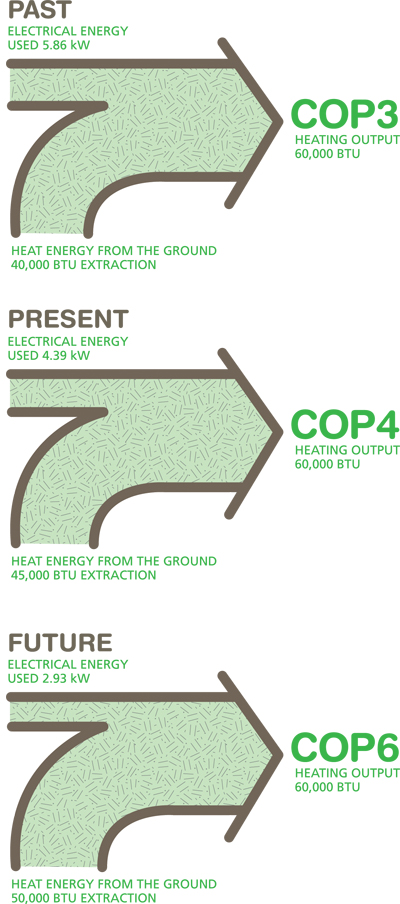

Supporting this new level of efficiency means the design of loop systems will need to be re-evaluated. When used for heating, geothermal heat pumps are rated by their COP (coefficient of performance). The COP measures the combination of the mechanical energy from the electricity needed to run the machine and the heat energy extracted from the ground. When heat pumps are sized properly, the combination of the two sources totals the energy necessary to heat a home or building.

Proportionately, we used a lot more electricity and less extracted energy from the ground in the past than we do today. Over the years, with advances in geothermal technology, more energy-efficient equipment was introduced, and we began to rely less on the electricity component and more on the energy extracted from the ground to achieve our goals. For example, 10 years ago, it took 20,000 British thermal units (5.86 kilowatts) of electricity and 40,000 BTUs of energy from the ground to heat a home requiring a heating output of 60,000 BTUs, resulting in a COP of three. Today, with more efficient equipment design, that same house has a COP of four, using 15,000 BTUs (4.39 kW) of electricity and 45,000 BTUs of energy from the ground.

In the coming year, we will see the introduction of geothermal equipment that pushes the envelope on energy efficiency, moving us towards a COP of six. For the first time ever, we will see a reduction in our reliance on electricity to as little as 10,000 BTUs (2.93 kW), while the energy being absorbed from the ground reaches 50,000 BTUs.

It’s great news that we’re becoming savvier when it comes to harnessing energy from the ground to heat and cool our buildings. But as this new, more efficient equipment hits the market, our increasing reliance on the earth’s energy means we need to pay even closer attention to the loop designs that will best support these new systems.

As the amount of electricity used to run the heat pump is decreased and the earth’s energy is more heavily relied on, longer or larger loop systems will be required to reduce undue stress on the ground. In the future, different loop configurations and enhanced grouting practices will emerge to support these more efficient systems.

The industry has seen several new and rehashed older helical vertical loop ideas in the past year as well as new lake loop and horizontal boring technology. Unfortunately most vertical ideas are unsuccessfully attempting to provide equal or better performance in smaller ground spaces. Shallow loops are dramatically affected the fluctuating annual moisture level found in unconsolidated formations and by the regional outdoor ambient temperature limiting reliable performance. Long term high performance is best served by deeper more the thermally stable rock formations below.

This is great news for the drilling industry as the more efficient geothermal equipment and redesigned loop systems should lead to the need for more drilling than ever before.

When this new equipment hits the market later this year, the geothermal industry will need to work hard to ensure that contractors, drillers and installers are aware of the importance of loop design in supporting these new systems.

The importance of selecting the right-sized equipment and loop systems to maximize heating and cooling efficiency hasn’t changed. What has changed is that, with equipment becoming more efficient, there’s an even greater focus now on designing the right loop systems to ensure maximum performance from these new systems and minimal stress to the ground.

Stan Marco is a well-respected and highly sought after geothermal knowledge expert and educator. He is an active member within the ground water community, a board member with the Canadian GeoExchange Coalition and co-founder and CEO of GeoSmart Energy & GeoSmart Drilling Services.

Print this page