Features

Research

Strategies & Innovations

The space between

Guidelines for drilling distances between wells for geothermal projects.

January 10, 2013 By Benjamin Hénault

I recently had a driller ask me what the minimum distance is between two wells for an open-loop ground-heat exchanger. It’s not an easy question to answer, as distance is not regulated.

I recently had a driller ask me what the minimum distance is between two wells for an open-loop ground-heat exchanger. It’s not an easy question to answer, as distance is not regulated.

In CSA C448 and other provincial/municipal water regulations, distance limitations are set up to eliminate the possibility of contaminating an aquifer. The purpose of having a distance between a production well and its recharge well is to prevent water recirculation within a water circuit. It is not a severe issue if a portion of water from the injection well returns to the production well because its temperature will increase over its trajectory. In fact, if the injection well is too close to the production well, the efficiency of the system will decrease during the season.

A ground water temperature at a depth of about 10 to 15 metres (35 to 50 feet) is constant except in rare cases. Above, ground temperature fluctuates with the outdoor temperature and below, it increases constantly at a gradient of approximately 1 F per 100 feet. Our goal is to capture entering water at the ground temperature and not close to the temperature at the exit of the heat pump.

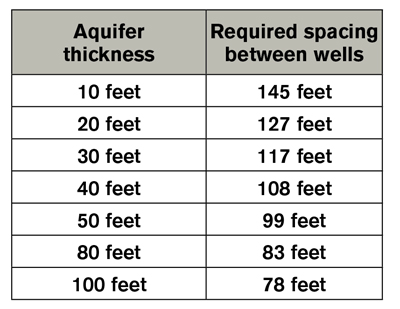

For a residential system, guidelines do recommend a minimum spacing of 100 feet. In reality, this distance must not be fixed; it depends on geological properties such as aquifer thickness, soil permeability, hydraulic gradient, pumping rate and the dominant load factor. In Kavanaugh and Rafferty’s ASHRAE reference book, guidelines are given to determine the minimum distance between the two wells. For example, a system operating in dominant mode for 210 days of the year with a soil porosity equivalent at 20 per cent and with a flow rate of 10 gallons per minute as a function of aquifer thickness, the minimum spacing will be:

|

This table shows that we need spacing more than 85 per cent longer for the 10-foot thickness compared to the 100-foot thickness. This example has specific parameters. Keep in mind that on-site conditions will never be precisely the same on any given job site due to local geology. This can be used as best practice, because the reference text has been established by one of the industry’s most relevant, reputable and professional engineering groups. However, don’t be surprised if the distance on your job site is different: a formal hydrogeology study done by a licensed professional geologist may allow you use greater or lesser spacing.

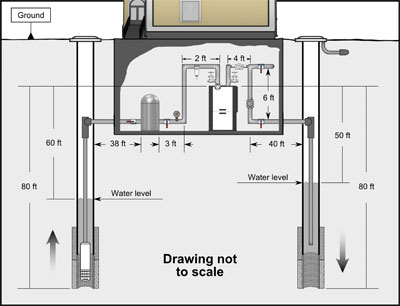

For the design step, a good approach is to evaluate which of the two wells is farther uphill to determine the aquifer’s flow direction. The aquifers’ relative positions can be found by measuring the water static level to a same reference point in each well. If they are in the same aquifer, the higher level is the uphill well. A pumping test can determine if they are in the same aquifer. The site of the production well must be uphill of the injection well, but this will not guarantee that the flow will go only to the downstream side. If the pumping rate is high enough, the cone of depression can reach the injection well in this case too.

There are also several important points to consider when planning the installation of a return well.

The return well’s diameter must be equal to or (preferably) greater than the diameter of the supply well, with a screen length greater than that of a supply well.

To prevent air entrainment, which stimulates encrustation, the drop pipe in the return well must terminate below the static water level in the well.

|

|

| Image courtesy of Canadian GeoExchange Coalition

|

Decrease the heat pump’s flow rate as much as you can to keep an acceptable exiting water temperature at the outlet of the heat pump for peak load conditions (about 1.5 gallons per minute TR). The exiting water temperature is usually optimized at about 36 F.

In summary, a ground water GHP system needs to be designed as required for a closed-loop system. If the designer has no experience with ground water geothermal systems, the designer must hire a hydrogeologist. Keep in mind that the above guideline of 100 feet between the wells is only applicable for residential applications. Finally, always verify that the specific regulations apply to your specific project’s jurisdiction.

It is foreseeable that this kind of issue will be subject to local authority regulations in the future.

Benjamin Hénault is a professional engineer. Since graduating from École de technologie supérieure, he has worked as the technical advisor at Canadian GeoExchange Coalition and is studying geothermal research for his masters degree at École Polytechnique de Montréal.

Print this page